ZF celebrates 60 years of automatic transmissions: over 35 million boxes produced

60 Years of ZF Innovation in Automatic Transmissions: A Journey from 3HP to the Electric Age

The Germans at ZF Friedrichshafen AG are celebrating a remarkable milestone in automotive history: 60 years of automatic transmission production. From its revolutionary debut in 1965 to today's modular architectures, ZF has assembled over 35 million units, setting industry standards for efficiency, comfort and performance.

The comfort offered by an automatic gearbox in everyday traffic is unparalleled, transforming it from a luxury into an essential feature. ZF has been a constant pioneer in this evolution, moving from purely mechanical systems to sophisticated, electronically controlled solutions adapted to hybridization.

A Brief History of ZF Innovation

The history of ZF automatic transmissions is a timeline of continuous innovations:

- 1965: The birth of the 3HP. Presented at the Frankfurt Motor Show, the 3HP (3-speed) transmission was a revolution. Robust, precise and modular (3HP12, 3HP20, 3HP22), it equipped prestigious brands such as BMW, Alfa Romeo and Maserati. Over a million units were produced by 1991.

- 1982: The first 4-speed transmission (4HP). It introduced electro-hydraulic control and a long ratio in fourth gear, helping to reduce fuel consumption. It was compatible with all-wheel drive and equipped models from Audi, Jaguar and Porsche.

- 1990s: The 5HP era. This generation introduced the first adaptive control, increasing sophistication and being widely adopted in the premium segment (Bentley, Rolls-Royce, Aston Martin). 4.1 million units were produced.

- 2001: The 6HP is introduced. With its modular architecture, low weight and ability to handle high torque, the 6HP was crucial, paving the way for modern hybrid platforms. Approximately 7 million units were produced.

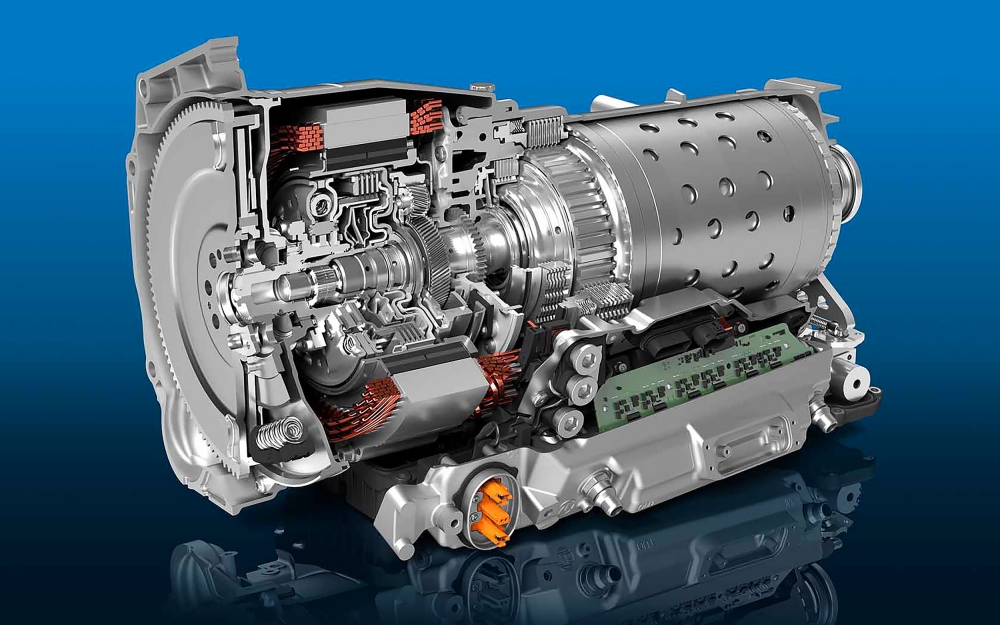

- 2009: 8HP Generation – Opening the Hybrid Era. This transmission defined a modular architecture (with 50% identical components between variants) that allowed the integration of the Start/Stop function and, progressively (2011-2015), hybrid versions that replaced the torque converter with an electric motor. To date, the 8HP has exceeded 25 million units and equipped a wide range of cars, from BMW and Audi to Dodge and Maserati.

- 2013: ZF 9HP. The first 9-speed automatic transmission for transverse-engined front-wheel drive cars. It excelled in efficiency thanks to its compact architecture.

- 2022: Gen. 4 of the 8HP. Responding to the rigors of electrification, it reduced CO2 emissions in PHEV configurations and allowed the integration of power electronics and a powerful electric motor (up to 160 kW).

- Present: 8HP Evo. A modular, scalable platform designed specifically for electrified drivetrains. It offers up to 200 kW of electric power and 600 Nm of electric torque, and is compatible with 48V-400V systems.

Romania's Key Role in the ZF Strategy

In addition to continuous innovation globally, ZF has consolidated an important strategic presence in Romania, the country becoming an essential pillar in both production and software development.

Major Investments in Timisoara and Oradea

ZF operates high-tech production facilities and engineering centers in Romania, contributing significantly to local development and the company's global innovation chain:

- Timisoara (ZF TRW Automotive Safety Systems): Safety Production: Although it does not produce transmissions, the Timisoara plant plays a vital role in the ZF portfolio, specializing in the production of components for automotive safety systems. Seat belts and airbags, essential for millions of cars worldwide, are manufactured here.

- Oradea (ZF Automotive Romania): Transmission Components: The Oradea unit is strategic for the transmission segment. Mechatronics and electronic components for ZF automatic gearboxes are produced here. The Oradea contribution provides the electronic and control heart of some of the most advanced ZF transmissions.

- Timisoara (Engineering and Development Center): Software and Electronics Innovation: The ZF Engineering Center in Timisoara is one of the most important in Eastern Europe. Romanian engineers work on software development for active and passive safety systems, autonomous driving and, in the context of electrification, power electronics and e-mobility solutions.

ZF's presence in Romania is not only an investment in production, but also in intelligence and innovation, integrating local talents directly into the development of future mobility technologies.

The Future of Automatic Transmissions: On the Road to E-Mobility

The 60th anniversary finds ZF in a race against time to adapt to electrification.

Although the transition to pure electric vehicles (BEV) eliminates the need for a conventional transmission, ZF continues to innovate for hybrid vehicles (MHEV/PHEV), where modern automatic transmissions (such as the 8HP Evo) play a central role. By integrating electric motors and power electronics into the transmission structure, ZF ensures that hybrid vehicles achieve the highest standards of performance and efficiency.

ZF's six-decade history in automatic transmissions is not just a collection of technological successes, but also a promise that the mobility of the future will be defined by the same dedication to innovation, efficiency and comfort.